Contact: Sonia (Manager)

Tel/Whatsapp: +86 15968770164

info@andamachinery.com

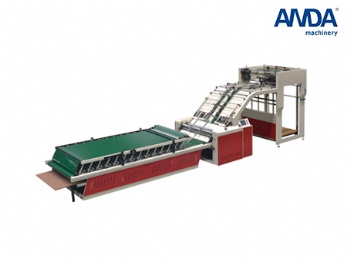

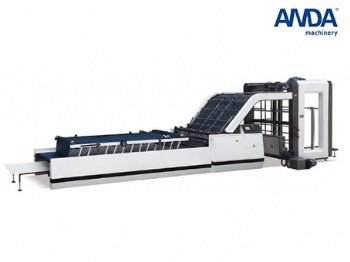

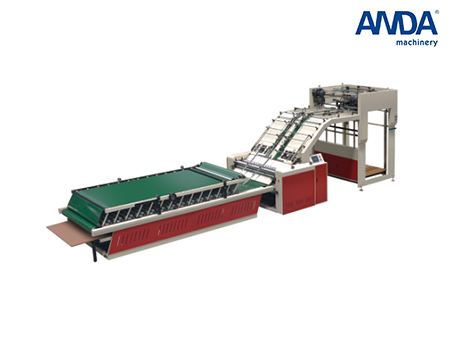

Automatic Flute Laminating Machine Model ADS1300

Category: Automatic Flute Laminating Machine

Name: Automatic Flute Laminating Machine Model ADS1300

Online Service:

Print this Page

Print this Page

|

Bookmark this

Bookmark this |

Skype Online

Skype Online |

E-mail Us

E-mail Us |

PDF Download PDF Download |

Click to see video

Click to see video |

| Prev Next | |

| Product Details | Send Inquiry |

|---|

Automatic Flute Laminating Machine Model ADS1300

Introduction:

This machine can be used to laminate cardboard to A/B/C/D/E corrugated board or cardboard which is more than 350g/m2.

Feature:

1.Air suction feeding is used for bottom paper. Automatic follow up and continuous feeding is achieved according to the speed of top paper;

2.Front feeding of top sheet manually by one person to make the feeding process more convenient and the laminating more accurate;

3.Advanced elastic front register is used for location and the bottom paper will never exceed. When laminating, it is very easy to make top paper and bottom paper alignment, or top sheet exceed;

4.Equipped with fully automatic glue supply system, the glue will be automatically supplied during lamination and recycled for saving glue consumption;

5.It is equipped with scientific design for linear speed of metering roller for avoiding glue thrown when high-speed running.

6.Imported touch screen is adopted and easy operation

7.Compared with other time-delay device or middle relay control, the bottom paper is transferred more precise and stable with PLC control system, Furthermore, speed is greatly increased and once circuit breakdown, it can automatically display and make alarm.

8.Clean the lower roller in gluing section by blade with circulated water; complete cleaning, convenient to replace the blade

9.Imported components are used in electrical section to ensure the machine run stably.

10.Floating movable pressing section is adopted to make the laminated paperboard smooth. This section can be moved front and back to take in paper conveniently.

11.Pressure of impression roller is one-side adjusted by nut of screw lead, convenient and fast.

12.Gear rack is used to control the lift and down of water tray and it will be easily taken out for cleaning

Technical parameters:

Model | ADS1300 |

Max. Sheet Size

| 1300×1100 mm

|

Min. Sheet Size

| 400×400 mm

|

Total power | 10KW |

Speed

| 0-90m/min

|

Weight

| 5000KG

|

Dimension

| 10000×2000×2400mm |

Español

Español English

English